|

|

Water heater |

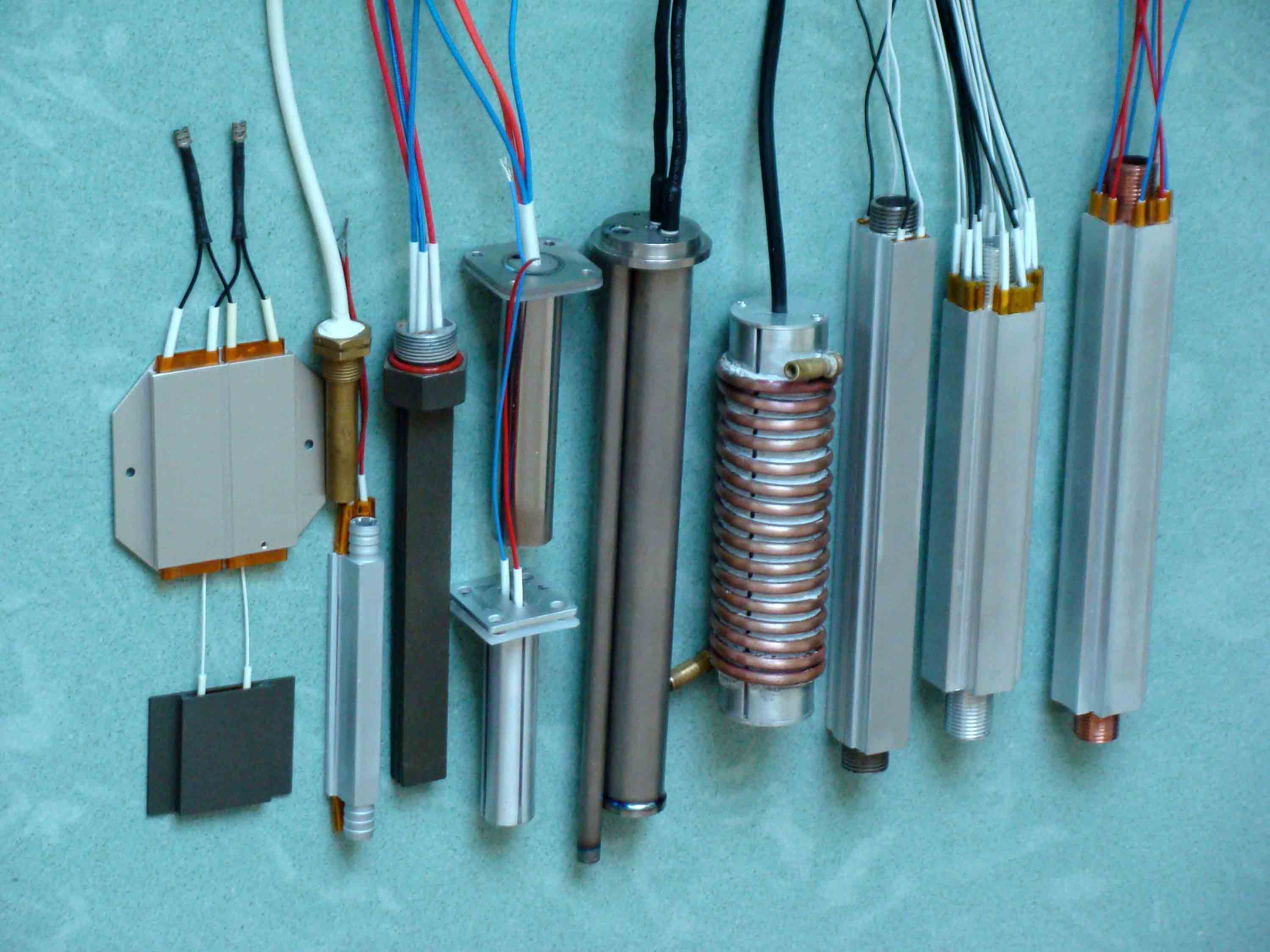

| 1. Configuration. |

|

| Type |

Specialty |

Excellence |

shortcoming |

Others |

| Transflux heater |

Water transflux hole of the heater |

Large power, quick heating |

Water must flow by itself or by a pump. |

Water can be heated in tap water supply |

Immerging

heater |

Heater immerge at bottom of water tank |

Heat quiet water, with uniform temperature |

Rising time is too long to heat the water in whole tank |

Fit for large power |

| Underside heater |

Heater is placed underside the tank |

Heat quiet water, with uniform temperature |

Rising time is too long to heat the water in whole tank |

Fit to maintain temperature of water |

| Double insulators heater |

With two layers insulators and two metal shells |

Top safety |

Higher cost |

No electric leakage on surface when PTC was burn |

| periphery of pipe heater |

Around the periphery of metal pipe |

The heater can contact the pipe very fit |

The power can not be large; energy can not be used very effectively |

Suitable for the situation the pipe can not be changed |

| Temperature control water heater |

With a temperature controller, the temperature of the water can be adjusted |

The temperature of water Can be controlled with accuracy of 4℃ |

Larger volume of the system, more cost. |

Suitable for the situation necessary to control the temperature of water |

|

Various materials.

1) Aluminium shell or pipe, it is not good in resistance to corrosion. Nickel plating or anti-corrosion coating could be better in preventing corrosion.

2) Brass or copper shell or pipe, it is good in resistance to corrosion. But it costs higher.

3) Ceramic shell, it’s good in resistance to corrosion. But its heating power could not be very large.

4) Stainless steel shell or pipe, it’s very excellence for preventing corrosion, and meets food safe standard. But it costs higher and has bigger bulk.. China patent number: ZL 2011 2022 0811.4, ZL 2011 2022 0805.9.

5) Anti-corrosion coated aluminum shell, it's corrosion resistance, but the cost is quite high. |

2. Some samples of uses.

PTC water heater could be used for shower, footbath, washing hand, vegetable and dish, drink warmer and boiler, fermenter, tea warmer, coffee wamer, milk warmer, vapor generator, sauna bath.

They could be used in heating diesel oil, gasoline or other liquid. Using PTC as a heating element could prevent the oil burning, it’s safer.

3. Notice in appliance.

PTC as a heating element, it fits for high safety, slap-up product. In some situations, it’s low cost and convenient.

The electric power of PTC water heater changes with the temperature of water. The higher is the temperature of water, the smaller is the power.

Using higher switch temperature PTC can get higher power, 220~270℃switch temperature PTC is selected usually. But if select too high switch temperature, the reliable will reduce.

4. Current products. |

| Immerging heater |

|

| |

Aluminium rectangle tube PTC heater

Part number |

Width |

Thickness |

Length in water |

Screw or flange |

Surface temp. |

Power |

| JSFLv-70L100W9.7T6-220V1 |

9.7 |

6 |

100mm |

M14 |

250℃ |

70W |

| JSFLv-150L100W13.2T6-220V1 |

13.2 |

6 |

100mm |

M20 |

250℃ |

150W |

| JSFLv-180L100W15.5T6-220V1 |

15.5 |

6 |

100mm |

M22 |

250℃ |

180W |

| JSFLv-350L100W16.5T11-220V1 |

16.5 |

11 |

100mm |

M24 or flange |

250℃ |

350W |

| JSFLv-250L100W21.5T6-220V1 |

21.5 |

6 |

100mm |

M25 or flange |

250℃ |

250W |

| JSFLv-450L100W21.5T12-220V1 |

21.5 |

12 |

100mm |

M30 or flange |

250℃ |

450W |

| JSFLv-2KL200W21.5T24-220V1 |

21.5 |

24 |

200mm |

M42 or flange |

250℃ |

2000W |

| JSFLv-1K8L200W31T12-220V1 |

31 |

12 |

200mm |

flange |

250℃ |

1800W |

| JSFLv-500L200W32T7-220V1 |

32 |

7 |

200mm |

flange |

250℃ |

500W |

| JSLv-1K8L200W65T7-220V1 |

65 |

7 |

200mm |

flange |

240℃ |

1800W |

|

| |

Aluminium cylinder tube PTC heater

Part number |

Diameter |

length |

Screw or flange |

Surface temp. |

Power |

| JSYLv-100L100D8-220V1 |

Φ8 |

100mm |

M12 |

250℃ |

100W |

| JSYLv-150L100D11-220V1 |

Φ11 |

100mm |

M14 |

250℃ |

150W |

| JSYLv-200L100D16-220V1 |

Φ16 |

100mm |

M20 |

250℃ |

200W |

| JSYLv-1K2L200D23-220V1 |

Φ23 |

200mm |

M30 |

250℃ |

1200W |

| JSYLv-1K8L200D33-220V1 |

Φ33 |

200mm |

M42 |

250℃ |

1800W |

| JSYLv-2K4L200D40-220V1 |

Φ40 |

200mm |

M48 |

250℃ |

2400W |

| JSYLv-6K5L500D48-220V1 |

Φ48 |

500mm |

M56 |

250℃ |

6500W |

|

| |

Aluminium +shape, and Δ shape tube PTC heater

Part number |

Width |

Thickness |

Length in water |

Screw or flange |

Surface temp. |

Power |

| JS+Lv-8KL400B39-220V1 |

39 |

39 |

400mm |

flange |

250℃ |

8000W |

| JS+Lv-10KL500B48-220V1 |

48 |

48 |

500mm |

flange |

250℃ |

10000W |

| JSΔLv-8KL500D42-220V1 |

|

Φ42 |

500mm |

M56 |

250℃ |

8000W |

|

| |

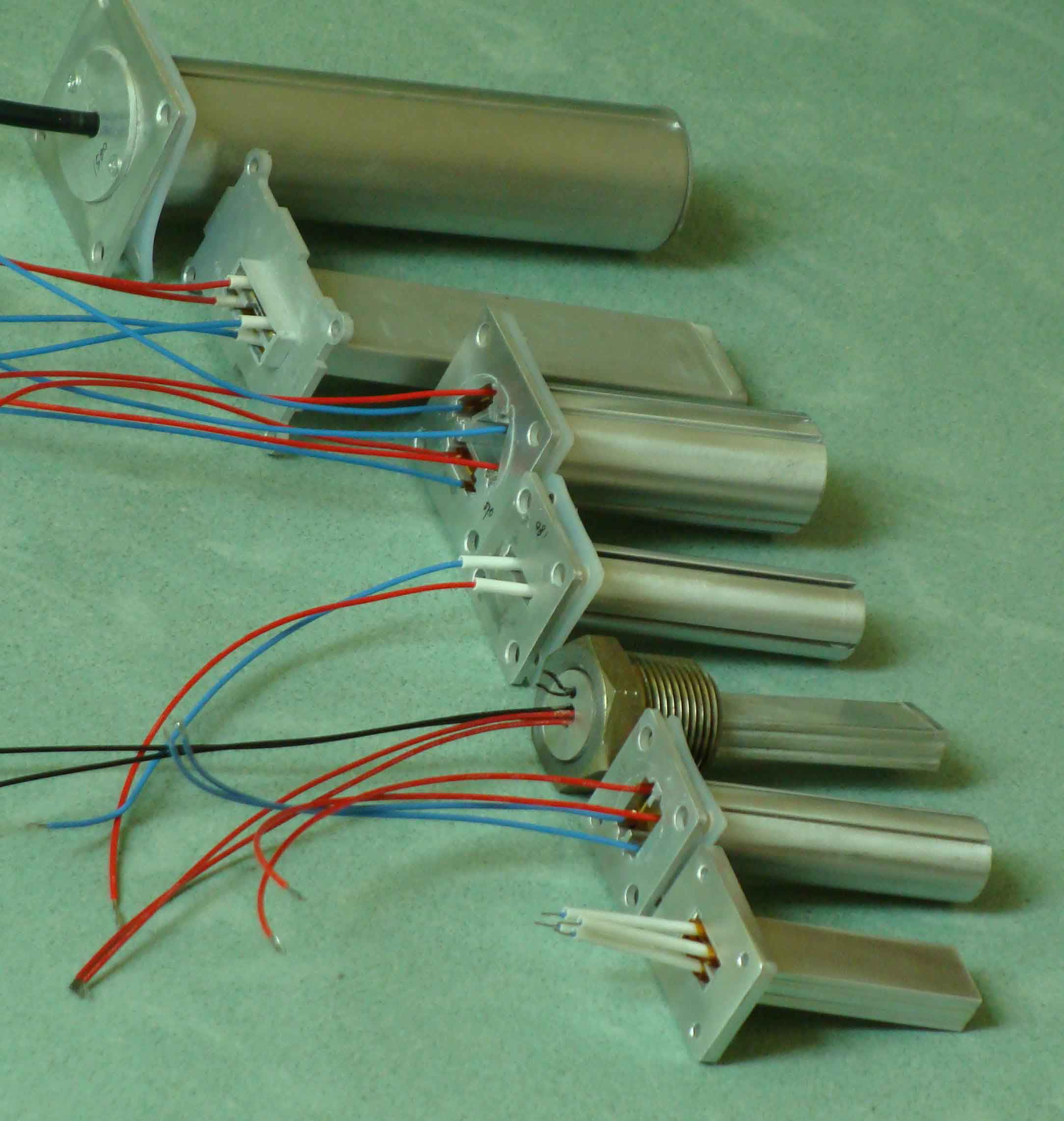

Aluminium T shape tube PTC heater

Part number |

Dimensions of heating part |

Dimensions of sealing plate |

Surface temp. |

Power |

| JSTLv-100L34W25T7-220V1 |

34/25/7 |

51/40 |

260℃ |

100W |

| JSTLv-200L40W32T7-220V1 |

40/32/7 |

51/45 |

260℃ |

200W |

| JSTLv-350L55W40T8-220V1 |

55/40/8 |

86/74 |

260℃ |

350W |

| JSTLv-800L55W40T15-220V1 |

55/40/15 |

86/74 |

260℃ |

800W |

|

| |

Stainless steel cylinder tube PTC heater

Part number |

Diameter |

length |

Screw or flange |

Surface temp. |

Power |

| JSBu-200L200D10-220V1 |

Φ10 |

200mm |

M14 or flange |

240℃ |

200W |

| JSBu-400L200D20-220V1 |

Φ20 |

200mm |

M24 or flange |

240℃ |

400W |

| JSBu-1K1L200D25-220V1 |

Φ25 |

200mm |

M30 or flange |

240℃ |

1100W |

| JSBu-2KL400D35-220V1 |

Φ35 |

400mm |

M42 or flange |

240℃ |

2000W |

| JSBu-3K8L400D45-220V1 |

Φ45 |

400mm |

M52 or flange |

240℃ |

3800W |

| JSBu-5K5L500D50-220V1 |

Φ50 |

500mm |

M56 or flange |

240℃ |

5500W |

| JSBu8-7KL500D50-220V1 |

Φ50 |

500mm |

M56 or flange |

230℃ |

7000W |

| JSBu2-900L200D25-220V1 double insulation |

Φ25 |

200mm |

M30 or flange |

240℃ |

900W |

| JSBu2-1K6L400D35-220V1 double insulation |

Φ35 |

400mm |

M42 or flange |

240℃ |

1600W |

| JSBuTE-700L200D25-220V1 teflon coating |

Φ25 |

200mm |

M30 or flange |

240℃ |

700W |

| JSBuTE-1K2L400D35-220V1 teflon coating |

Φ35 |

400mm |

M42 or flange |

240℃ |

1200W |

|

| |

Titanium cylinder tube PTC heater

Part number |

Diameter |

length |

Screw or flange |

Surface temp. |

Power |

| JSTi-200L200D10-220V1 |

Φ10 |

200mm |

M14 or flange |

240℃ |

200W |

| JSTi-400L200D10-220V1 |

Φ20 |

200mm |

M24 or flange |

240℃ |

400W |

| JSTi-1K1L200D10-220V1 |

Φ25 |

200mm |

M30 or flange |

240℃ |

1100W |

| JSTi-2KL400D10-220V1 |

Φ35 |

400mm |

M42 or flange |

240℃ |

2000W |

| JSTi-3K8L400D10-220V1 |

Φ45 |

400mm |

M52 or flange |

240℃ |

3800W |

| JSTi-5K5L500D10-220V1 |

Φ50 |

500mm |

M56 or flange |

240℃ |

5500W |

| JSTi2-7KL500D10-220V1 |

Φ50 |

500mm |

M56 or flange |

240℃ |

7000W |

|

| |

Notice:

1) PTC heating tube can be operated without water, low water level, incrustant depositing.

2)Applied voltage could be 12~72V, 100~600V. Two applied voltages in one heater; three phase voltage are possible.

3) The length of heating part could be selected between 50~800mm, the longer is the shell, the larger is the power.

4) The connected screw or flange could be customer made.

4) The connected screw or flange could be customer made.

5) The surface temperature without water, could be between 50~260℃, the higher is this temperature, the larger is the heating power.

6) The stable temperature of water would be affected by the heating power, cubage of water, the shape and material of container, heating dispersion, evaporating of water, temperature controller.

7) The tube can be consist of aluminum, copper, brass, 304/316/316L stainless steel, titanium, monel alloy. The life time for aluminum tube is around 2years, for stainless steel is around 5years continuously operation.

8) For preventing corrosion, the surface of tube can be coated with Teflon, used for heating element in electroplate tank is possible.

9) A thermostat or thermo-couple or sensor can be assembled in the tube for controlling the temperature of water.

10)TUV approval number: B 09 06 46746 004,B 09 08 16746 008.

11)National patent, ZL 2010 2 01356626.0, high power density water heater.

National patent, ZL 201320630141.2, surround PTC heating tube.

National patent, ZL 2011 2022 0811.4, anti-corrosion PTC heating tube.

National patent, ZL 2011 2012 6016.9, Used for special high security, there are 2 layers of insulator and 2 layers of metal protective layer. That can prevent the electricity leakage on the heater caused by breakdown of PTC ceramic.

National patent, ZL 201520425957.0, PTC heating element used in electroplate tank.

National patent, ZL 201520103573.7, PTC heating element used in three phases.

National patent, ZL 201520103574.1 PTC heating element applied with multi voltage. |

| |

Transflux water heater: |

.jpg)

|

|

| |

Aluminium pipe PTC transflux water heater

Part number |

Width |

Height |

Diameter of pipe |

Length |

Screw of pipe |

Surface temp. |

Power |

| TSLv-380L150W21.5T20.5D10-220V1 |

21.5 |

20.5 |

Φ10 |

150 |

2/8” |

240℃ |

380W |

| TSLv-400L150W21.5T20.5D13-220V1 |

21.5 |

23.5 |

Φ13 |

150 |

3/8” |

240℃ |

400W |

| TSLv-1K2L200W21.5T25D13-220V1 |

21.5 |

25 |

Φ13 |

200 |

3/8” |

240℃ |

1200W |

| TSLv-1K5L200W33T48D26-220V1 |

33 |

48 |

Φ26 |

200 |

1” |

240℃ |

1500W |

| TSLv-8KL500W39T39D16-220V1 |

39 |

39 |

Φ16 |

500 |

4/8” |

240℃ |

8000W |

| TSLv-10KL500W48T48D15-220V1 |

48 |

48 |

Φ15 |

500 |

4/8” |

240℃ |

10000W |

| TSLv-7K5L500WD48D25-220V1 |

Φ48 |

|

Φ25 |

500 |

1” |

240℃ |

7500W |

TSLv2-8KL500W48T48D15-220V1

double insulation |

48 |

48 |

Φ15 |

500 |

4/8” |

240℃ |

8000W |

TSLv-1K2L130W33T48D5-220VY

kitchen ventilator washing heater |

33 |

48 |

Φ5 |

130 |

|

260℃ |

1200W |

|

| |

Stainless steel/titanium/copper pipe PTC transflux water heater

Part number |

Width |

Height |

Diameter of pipe |

Length |

Screw of pipe |

Surface temp. |

Power |

| TSBu-1KL250W26T36D15-220V1 SUS 304 |

26 |

36 |

Φ15 |

250mm |

4/8” |

250℃ |

1000W |

| TSBu-1K8L250W36T36D15-220V1 SUS 304 |

36 |

36 |

Φ15 |

250mm |

4/8” |

250℃ |

1800W |

| TSTo-2KL250W36T36D15-220V1 copper |

36 |

36 |

Φ15 |

250mm |

4/8” |

250℃ |

2000W |

| TSBu-8KL550WD48D15-220V1 SUS 304 |

Φ48 |

|

Φ28 |

550mm |

1” |

240℃ |

6000W |

| TSTi-1KL250W26T36D15-220V1 titanium |

26 |

36 |

Φ15 |

250mm |

4/8” |

250℃ |

1000W |

| TSTi-1K8L250W36T36D15-220V1 titanium |

36 |

36 |

Φ15 |

250mm |

4/8” |

250℃ |

1800W |

|

| |

Twine pipe PTC transflux water heater with cylinder tank

Part number

|

Out diameter |

Pipe diameter |

Thickness of pipe |

length |

Surface temp. |

Power |

| TSTo-300L100WD28D3-220V1 |

Φ28 |

Φ3 |

0.3 |

100mm |

240℃ |

300W |

TSTo-500L100WD35D5-220V1

copper pipe |

Φ35 |

Φ5 |

0.4 |

100mm |

240℃ |

500W |

TSTo-1K6L130WD50D5-220V1

copper pipe |

Φ50 |

Φ5 |

0.4 |

130mm |

250℃ |

1600W |

TSTo-2K5L150WD60D5-220V1

copper pipe |

Φ60 |

Φ5 |

0.4 |

150mm |

250℃ |

2500W |

| TSLv-1K6L130WD50D5-220V1 aluminium pipe |

Φ50 |

Φ5 |

0.4 |

130mm |

250℃ |

1600W |

TSLv-1K4L130WD50D5-220V1

SUS304 pipe |

Φ50 |

Φ5 |

0.4 |

130mm |

250℃ |

1400W |

|

| |

PTC transflux water heater with cylinder tank

| Part number |

Height of tank |

Diameter of tank |

Screw connector |

Temperature of heating tube |

Power |

| TSSC-1K4L200WD50G4-220V1 |

200 |

50 |

4/8” |

250℃ |

1.4KW |

| TSSC-2K5L200WD80G6-220V1 |

200 |

80 |

6/8” |

250℃ |

2.5KW |

| TSSC-20KL400WD220G8-220V1 |

400 |

220 |

1” |

250℃ |

20KW |

| TSSC-40KL600WD300G16-220V1 |

600 |

300 |

2” |

250℃ |

40KW |

|

| |

Notice:

1) PTC heating tube can be operated without water, with incrustant depositing, for water evaporating.

2) Applied voltage could be 12~72V, 100~600V. Two applied voltages in one heater; three phase voltage are possible.

3) The length could be selected properly by customers, between 50~500mm, the longer is the shell, the larger is the power.

4) The connected terminal, diameter, shape, could be customer made.

5) The tube can be consist of aluminum, copper, brass, 304/316/316L stainless steel, titanium, monel alloy. The life time for aluminum tube is around 2years, for stainless steel is around 5years continuously operation.

6) The surface temperature without water, could be between 50~260℃, the higher is this temperature, the larger is the power.

7) The out-water temperature could be affected by heating power, rate of flow water, heating dispersion.

8) A thermostat or thermo-couple or sensor can be assembled at the out-water end of heating tube for controlling the temperature of out-water.

9)TUV approval number: B 09 06 46746 004,B 09 08 16746 008.

10) National patent, ZL 2010 2 01356626.0, high power density water heater.

National patent, ZL 2011 2022 0811.4, anti-corrosion PTC heating tube.

National patent, ZL 2011 2012 6016.9, Used for special high security, there are 2 layers of insulator and 2 layers of metal protective layer. That can prevent the electricity leakage on the heater caused by breakdown of PTC ceramic.

National patent, ZL 2012 20370684.0, twine pipe water heater.

National patent, ZL 2012 2 0178696.3, high power density PTC heating pipe.

National patent, ZL 201320630141.2, surround PTC heating tube.

National patent, ZL 201520425957.0, PTC heating element used in electroplate tank.

National patent, ZL 201520103573.7, PTC heating element used in three phases.

National patent, ZL 201520103574.1 PTC heating element applied with multi voltage. |

| |

Consumed power for transflux water heater

Flux of water |

Initial temperature |

Final temperature |

Heating efficiency |

Consumed power |

Stable current on 220V voltage |

| 1L/ min |

20℃ |

40℃ |

90% |

1.5KW |

6.8A |

| 3L/ min |

20℃ |

40℃ |

90% |

4.5KW |

20.5A |

| 5L/ min |

20℃ |

40℃ |

90% |

7.8KW |

35.5A |

| 10L/ min |

20℃ |

40℃ |

90% |

15.6KW |

70.9A |

|

| |

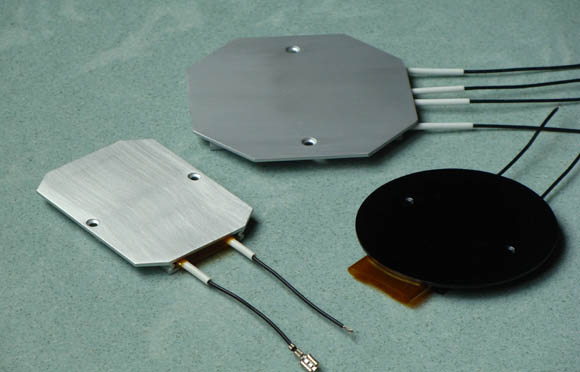

| Underside water heater: |

|

| Part number |

Length |

Width |

Thickness |

Surface temperature in air |

Power put under an aluminium cup |

| TD-120L65W25T7-220V1 |

65mm |

25 |

7 |

260℃ |

120W |

| TD-200L65W25T12-220V1 |

65mm |

25 |

12 |

260℃ |

200W |

| TD-100L45W35T7-220V1 |

45mm |

35 |

7 |

260℃ |

100W |

| TD-350L60W48T12-220V1 |

60mm |

48 |

12 |

260℃ |

350W |

| TD-240L80W63T7-220V1 |

80mm |

63 |

7 |

260℃ |

240W |

| TD-600L120W90T7-220V1 |

120mm |

90 |

7 |

260℃ |

600W |

| TD-300D85T7-220V1 |

Φ85mm |

|

7 |

260℃ |

300W |

|

Notice:

1) Applied voltage could be 12~36V, 100~600V.

2) The length of the plate could be selected by customer between some range, larger power could be reached with larger plate. But larger plate might result bad heating conduction because the connecting gap on interface.

3) The surface temperature without water, could be between 80~260℃, the higher is this temperature, the larger is the power.

4) The stable temperature of water could be affected by the power of PTC, cubage of water, the shape and material of container, heating dispersion, vapor of water.

5) TUV approval number: B 09 06 46746 004,B 09 08 16746 008.

6)National patent, patent number ZL 2010 2 01356626.0 |

| |

Heater around pipe: |

|

| Part number |

Inner diameter |

Length |

Width |

Height |

Surface temperature |

Power at 25℃ water |

| WT-80L100DIN10-220V1 |

Φ10 |

100 mm |

20 |

25 |

240℃ |

80W |

| WT-200L100DIN20-220V1 |

Φ20 |

100 mm |

38 |

35 |

260℃ |

200W |

| WT-280L100DIN25-220V1 |

Φ25 |

100 mm |

40 |

39 |

260℃ |

280W |

| WT-340L100DIN32-220V1 |

Φ32 |

100 mm |

47 |

45 |

260℃ |

340W |

| WT-500L200DIN35-220V1 |

Φ35 |

200 mm |

50 |

47 |

260℃ |

500W |

| WT-800L200DIN65-220V1 |

Φ65 |

200 mm |

81 |

79 |

260℃ |

800W |

| WT-1K2L200DIN76-220V1 |

Φ76 |

200 mm |

92 |

90 |

260℃ |

1200W |

| WT-1K5L200DIN93-220V1 |

Φ93 |

200 mm |

110 |

107 |

260℃ |

1500W |

| WT-1K6L200DIN108-220V1 |

Φ108 |

200 mm |

125 |

122 |

260℃ |

1600W |

| WT-1K8L200DIN118-220V1 |

Φ118 |

200 mm |

135 |

132 |

260℃ |

1800W |

|

Notice:

1) Voltage could be selected 12V, 24V, 36V, 100~120V, 220~240V, 380V, 600V.

2) Length could be between 50mm and 500mm.

3) The surface temperature without water, could be between 80~260℃, the higher is this temperature, the larger is the power. |

| |

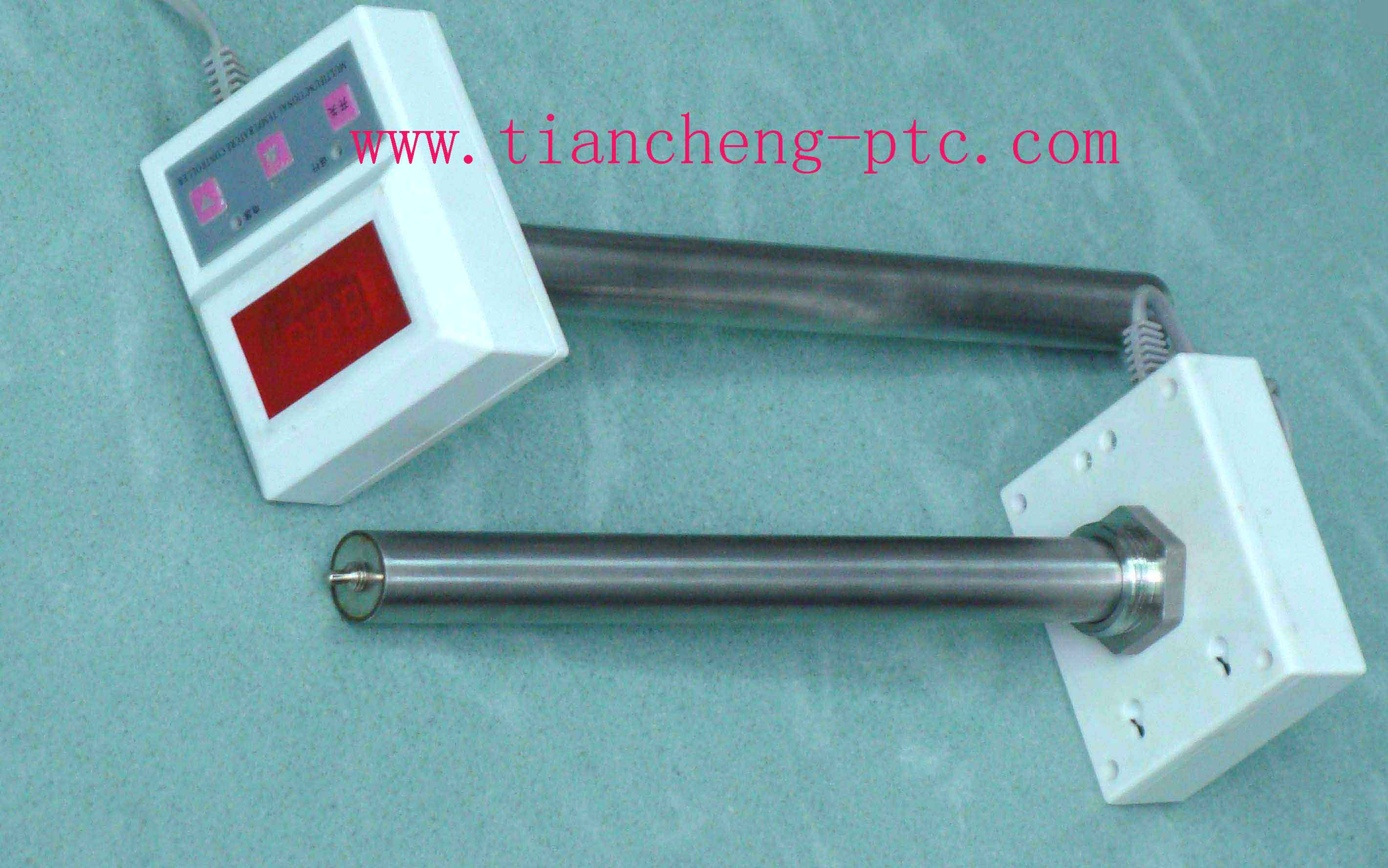

Liquid heater with temperature controller |

|

Notice:

1) The temperature of water could be controlled by adding a temperature controoler, or thermostat.

2) The power can be customer’required.

3) Volltage can be 12~600V or other voltage.

4) UL file for PTC pellet is E 207611.

5) Temperature control tolerance is ±2℃. |

| |

Tiancheng Thermistors Co., Ltd.

Add: No. 6, Xinfenglu road, Dabeiwan, Changping, Daojiao town, Dongguan, Guangdong, China,

Post code: 523041

Tel: 86-769-22271712, 22175083, 22185107, 22285948

Fax: 86-769-22278428

Contact:

Ms. Zhao, tel&wechat 13725732994

Ms. Shan, tel&wechat 13544682427

Mr. Zhu,

tel&wechat 13602318093

QQ:1539872297

Skype: Xiaorong Zhu , S.Yang-PTC

E-mail: tcptc@tiancheng-ptc.com |

|

|

|

|