|

|

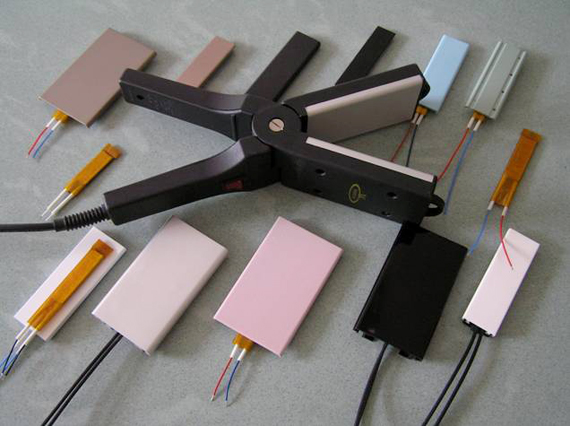

Straightener and wave plate |

Use:

Use the hot straightener to straighten hair; and use the wave plate with various waves to make the hair into wave hairstyles. The temperature on straightener or wave plate is controlled between 180~220℃ usually.

Classify:

- Classify by controlling method.

Type |

Specialty |

Excellence |

shortcoming |

Others |

PTC self-

controlled heater |

The temperature can be controlled by PTC itself. |

Low cost, temperature controller is not needed. |

Lower temperature rising |

Used in smaller plate |

PTC heater, with a controlled circuit |

PTC with higher temperature, but the temperature is controlled at lower level. |

rapid temperature rising. |

Higher cost. |

Used in bigger plate |

- Classify by materials of the straightener plate.

Type |

Specialty |

Excellence |

shortcoming |

Others |

Aluminum plate coated with ceramic coating |

Paint a ceramic coat on the surface of aluminum plate |

Various colors, lower cost, fast temperature rising |

The coating is not very long life |

Ion powder, tourmaline powder can be added to the coat |

Aluminum plate coated with Teflon coating |

Paint a layer Teflon on the surface of aluminum plate |

Easy to clear, no viscidity on hair, fast temperature rising |

Only black color, not very handsome |

|

Aluminum plate oxygenated |

Aluminum plate is oxygenated on surface |

lower cost, with special bright color |

Color is not very stable at high temperature |

There is several color such as gray, black, golden, brown |

Alumina ceramic plate polished |

Alumina ceramic plate, and its surface is polished |

No coating, very bright. |

Lower temperature rising, easy to dirty |

There is several color such as black, white |

Alumina ceramic plate glazied |

Alumina ceramic plate coated by a glazing on surface |

Long life, bright, easy to clear |

Lower temperature rising, higher cost |

There is several color such as black, red, green, white |

|

| |

Notice in use:

To obtain fast temperature rising, notice: 1)use PTC heater with higher temperature and add a controlling circuit to control the temperature. 2)use PTC with larger area. 3)use straightener plate with good heat conduct, such as aluminum, and enhance heat dispersion from PTC to the plate. 4)use PTC with larger inrush current.

Straighteners also be made with steam hole to generate steam. Stream is useful for straighten hair and protect hair.

PTC heating element can be applied on very wide voltage, for example, 100V~230V. The surface temperature increases (or decreases) about 8℃, when supplied voltage increases (or decreases) 2 time for same PTC. 100V~230V voltage is selected in most appliances, but 12V~24V is selected in a few situation.

The stable power of most straighteners is 20~40W; but power is larger when straightnening, may be 80W to 200W.

Commonly used products

Our company can supply PTC straightener plate, PTC heater with insulating film, or PTC heating pellet. But for getting rapid temperature rising, uniform temperature, good insulation, the PTC straightener plate is commended firstly.

Our PTC straightener plates are selected by many known customer, such as, Philip, Toshiba, Sanyo, Panasonic, and so on. |

| |

Straightener plate usually used:

Part number |

Length |

Width |

Thickness |

Materials |

Surface process |

Color on surface |

572/598 |

100 |

60 |

8.8 |

Aluminum |

Ceramic paint coating |

Various color |

584/569 |

83 |

15 |

10.5 |

Aluminum |

Ceramic paint coating |

Various color |

541P |

90 |

25 |

10.8 |

Aluminum |

Ceramic paint coating |

Various color |

543 |

90 |

34 |

7.5 |

Aluminum |

Ceramic paint coating |

Various color |

566 with stream holes |

100 |

26 |

11.3 |

Aluminum |

Ceramic paint coating |

Various color |

567 |

100 |

60 |

10.5 |

Aluminum |

Ceramic paint coating |

Various color |

568 with arc convexity |

90 |

44 |

10 |

Aluminum |

Ceramic paint coating |

Various color |

568 |

90 |

44 |

8.5 |

Aluminum |

Ceramic paint coating |

Various color |

568 with arc concave |

90 |

44 |

14.8 |

Aluminum |

Ceramic paint coating |

Various color |

571 |

90 |

28 |

7.5 |

Aluminum |

Ceramic paint coating |

Various color |

574 |

90 |

24.85 |

10.6 |

Aluminum |

Ceramic paint coating |

Various color |

575 |

90 |

40 |

7.8 |

Aluminum |

Ceramic paint coating |

Various color |

575P |

80 |

33 |

7.5 |

Aluminum |

Ceramic paint coating |

Various color |

578 with arc convexity |

90 |

24 |

10.5 |

Aluminum |

Ceramic paint coating |

Various color |

578 with arc concave |

90 |

25 |

12 |

Aluminum |

Ceramic paint coating |

Various color |

585 |

90 |

44 |

8.7 |

Aluminum |

Ceramic paint coating |

Various color |

587 with arc convexity |

90 |

41 |

9.6 |

Aluminum |

Ceramic paint coating |

Various color |

587 with arc concave |

90 |

41 |

12.8 |

Aluminum |

Ceramic paint coating |

Various color |

597 |

89.5 |

25 |

8 |

Ceramic |

Polished plate |

Various color |

597 |

90 |

25 |

8 |

Aluminum |

Ceramic paint coating |

Various color |

605 |

90 |

25 |

8.5 |

Aluminum |

Ceramic paint coating |

Various color |

614 |

90 |

30.8 |

10.5 |

Aluminum |

Ceramic paint coating |

Various color |

615 |

90 |

57 |

10.5 |

Aluminum |

Ceramic paint coating |

Various color |

619P |

83 |

20 |

6 |

Aluminum |

Ceramic paint coating |

Various color |

622 |

90 |

34 |

12 |

Aluminum |

Ceramic paint coating |

Various color |

636 with stream holes |

90 |

31 |

11 |

Aluminum |

Ceramic paint coating |

Various color |

638K |

90 |

24 |

10.5 |

Aluminum |

Ceramic paint coating |

Various color |

641 |

90 |

31 |

11.5 |

Aluminum |

Ceramic paint coating |

Various color |

647 |

90 |

26 |

8.8 |

Aluminum |

Ceramic paint coating |

Various color |

650 |

90 |

25 |

7 |

Aluminum |

Ceramic paint coating |

Various color |

679 |

90 |

26 |

10.5 |

Aluminum |

Ceramic paint coating |

Various color |

680 with stream holes |

90 |

60 |

7.1 |

Aluminum |

Ceramic paint coating |

Various color |

903 |

90 |

30 |

7 |

Aluminum |

Ceramic paint coating |

Various color |

906 |

90 |

54 |

7 |

Aluminum |

Ceramic paint coating |

Various color |

907 |

90 |

25 |

6.6 |

Aluminum |

Ceramic paint coating |

Various color |

908 |

90 |

39.5 |

6.6 |

Aluminum |

Ceramic paint coating |

Various color |

6218 |

90 |

35 |

7.4 |

Aluminum |

Ceramic paint coating |

Various color |

WIN plate |

90 |

28 |

9 |

Ceramic |

Polished |

Various color |

027 |

100.9 |

57.1 |

13.55 |

Aluminum |

Ceramic paint coating |

Various color |

028 |

100.8 |

51.5 |

13.5 |

Aluminum |

Teflon coated |

Black |

044 |

109 |

53.3 |

11.65 |

Aluminum |

Ceramic paint coating |

Various color |

047 with stream holes |

100.5 |

54.9 |

11 |

Aluminum |

Ceramic paint coating |

Various color |

048 |

100.9 |

57.2 |

13.5 |

Ceramic&aluminum |

Polished surface |

Various color |

049 |

100.9 |

57.1 |

13.55 |

Aluminum |

Oxygenated |

Various color |

Note: 1) customer fond color is possible.

2) surface temperature is 220℃ usually, or customer required. |

| |

|

| |

|

| |

Tiancheng Thermistors Co., Ltd.

Add: No. 6, Xinfenglu road, Dabeiwan, Changping, Daojiao town, Dongguan, Guangdong, China,

Post code: 523041

Tel: 86-769-22271712, 22175083, 22185107, 22285948

Fax: 86-769-22278428

Contact:

Ms. Zhao, tel&wechat 13725732994

Ms. Shan, tel&wechat 13544682427

Mr. Zhu,

tel&wechat 13602318093

QQ:1539872297

Skype: Xiaorong Zhu , S.Yang-PTC

E-mail: tcptc@tiancheng-ptc.com |

|

|

|